Visibility

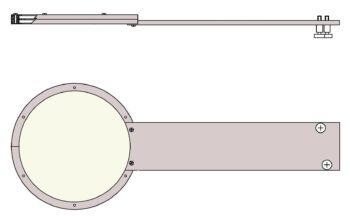

The 8364 Dual Technology Visibility Sensor measures transparency of the atmosphere and calculates its extension coefficient and meteorological optical range (MOR) values. Using both direct attenuation and forward scatter technologies the 8364 can measure airborne particle sizes once available only from a transmissometer while having the reliability and cost effectiveness of a forward scatter visibility sensor. Its precision makes it ideal for applications requiring the highest in performance and reliability, such as aviation and meteorological studies.

The 8364 Dual Technology Visibility Sensor measures transparency of the atmosphere and calculates its extension coefficient and meteorological optical range (MOR) values. Using both direct attenuation and forward scatter technologies the 8364 can measure airborne particle sizes once available only from a transmissometer while having the reliability and cost effectiveness of a forward scatter visibility sensor. Its precision makes it ideal for applications requiring the highest in performance and reliability, such as aviation and meteorological studies.

Accurate measurement of visibility in all weather conditions, including heavy precipitation, fog and snow is limited in other sensors. Two-headed forward scatter visibility sensors that rely solely on light scattering techniques are blind to certain size airborne particles that do not reflect light. By measuring both the light attenuation and light scattering at the same time the 8364 computes ratio-metric values to derive the most accurate answer. This measuring process cancels several variables during calculation and ensures that the visibility measurement is not affected by contaminants on the lenses, or by temperature effects on the emitters and electronics.

By having two direct attenuation and two scatter values for every measurement the 8364 does not have to depend upon absolute measurements to be the most accurate sensor available today. This advantage means that measurements are independent of the effects of the environment, thereby maximizing accuracy, reducing recurring calibration, and minimizing maintenance requirements.

Every 8364 is calibrated through a scientifically valid chain of reference. The response of the calibration device can be clearly traced to the “FAA golden standard transmissometer” at the FAA testing facility. This standard was established in direct comparison during certification of the sensor for aviation quality measurements.

If one of the heads should fail the four-head configuration allows for continued operating with only three sensor heads. Built-in test (BIT) functions report the sensor head failure so that appropriate maintenance can be scheduled. The BIT functions also monitor power supply voltages, heater status, and indications of abnormal operation.